Clutch Component Diagnostic Tool

Clutch Component Diagnostic Tool

Answer the questions below to identify which clutch components may need inspection or replacement.

1. What symptoms are you experiencing?

2. Is the clutch pedal feeling different than usual?

3. Do you hear any unusual noises?

When you finally decide to tackle a clutch replacement, the temptation is to focus on the clutch disc alone. In practice, the clutch works as a team - the disc, pressure plate, flywheel, and a handful of hydraulic parts all share the load. Swapping just one piece can leave you with premature wear, rattles, or even a new set of headaches soon after the job is done. Below is a no‑nonsense guide that walks you through every component that should be inspected, and often replaced, when you’re already pulling the old clutch out.

Understanding the Complete Clutch Kit

Before you reach for a wrench, it helps to know exactly what makes up a modern clutch assembly. The first definition below marks the core of the kit.

Clutch Kit is a collection of components - typically a clutch disc, pressure plate, release bearing, and the associated hardware - that together transmit engine torque to the gearbox while allowing the driver to disengage power on demand. Manufacturers bundle these parts because they wear at similar rates and are engineered to work as a unit.

Most aftermarket kits also include a new pilot bearing, a clutch alignment tool, and sometimes a fresh set of bolts. Buying the full kit ensures you’re matching the friction material, spring rate, and surface finish, which keeps the engagement smooth and the lifespan predictable.

Flywheel: The Unsung Hero

Even if your flywheel looks pristine, it’s the perfect time to give it a once‑over. A damaged or warped flywheel can cause vibration, chatter, or a soft clutch feel.

Flywheel is a heavy, disc‑shaped component bolted to the engine crankshaft that stores rotational energy and provides a friction surface for the clutch disc. Modern cars often use a dual‑mass flywheel (DMF) to smooth out engine torque pulses, but they are more complex and expensive to replace.

If you spot deep scoring, heat‑tinting, or a wobble when the flywheel is rotated by hand, replace it. Many performance shops offer resurfacing services, but only if the thickness is still within spec - typically a minimum of 2.0 mm of material left after grinding.

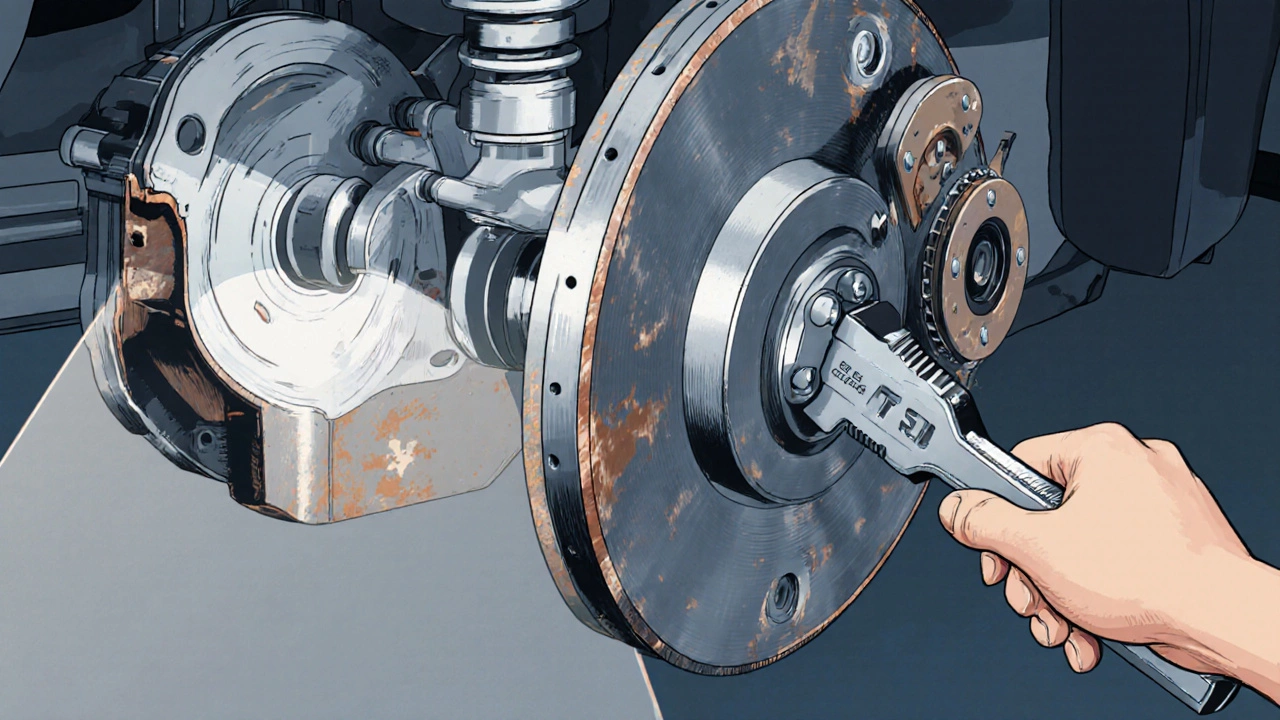

Pressure Plate and Clutch Disc: The Core Friction Pair

The pressure plate pushes the clutch disc against the flywheel. If either component is worn, the clutch will slip or feel mushy.

Pressure Plate is a spring‑loaded casting that clamps the clutch disc to the flywheel when the clutch pedal is released. It contains multiple diaphragm springs that provide the clamping force.

Clutch Disc is the friction element sandwiched between the pressure plate and the flywheel, covered with a composite material that transfers engine torque to the transmission input shaft.

When inspecting, look for heat spots, cracking, or worn splines on the disc. The pressure plate should be checked for bent springs, cracks, and even‑ness of the friction surface. Most mechanics replace both together - the cost difference is negligible compared to the potential for future failure.

Release (Throw‑out) Bearing: The Silent Rotator

The release bearing allows the pressure plate to disengage when you press the clutch pedal. A failing bearing will make a whining or grinding noise that gets louder as the vehicle speeds up.

Release Bearing is a spherical bearing that sits between the clutch fork (or hydraulic piston) and the pressure plate, providing a smooth, low‑friction surface for disengagement.

Because the bearing runs in constant contact with the rotating pressure plate, replace it whenever you’re in the shop. It costs a fraction of the kit price and saves you a second trip.

Hydraulic System: Master, Slave, and Lines

If your car uses a hydraulic clutch - which most modern cars do - you have a few more pieces that age alongside the mechanical parts.

Clutch Master Cylinder is a piston‑driven device mounted on the firewall that converts pedal force into hydraulic pressure.

Clutch Slave Cylinder is a smaller hydraulic actuator located near the transmission that receives pressure from the master cylinder and pushes the release bearing.

Hydraulic Line is a flexible tube that carries fluid between the master and slave cylinders. Over time, the line can develop micro‑cracks or absorb moisture, leading to spongy pedal feel.

Even if the pedal feels firm, it’s wise to bleed the system and replace any aged line. A new master or slave cylinder is inexpensive and prevents a sudden loss of clutch operation.

Pedal, Cable, and Alignment: Keeping the Engagement Precise

Older cars may still use a cable‑actuated clutch. Whether hydraulic or cable‑driven, the pedal mechanism can develop play that throws off clutch bite.

Clutch Pedal is the foot‑operated lever that initiates clutch disengagement. Wear in the pivot points can create excess free play.

Clutch Cable (if applicable) transfers pedal motion to the release bearing. Cables stretch and corrode, especially in salty climates.

A clutch alignment tool is a cheap but essential piece that ensures the disc sits perfectly centered on the flywheel. Misalignment can cause uneven wear and premature bearing failure.

Engine and Transmission Mounts: The Foundation

While you’re down there, give the engine mounts a visual check. A cracked or sagging mount can add stress to the clutch during launch.

Engine Mount is a rubber‑filled metal bracket that isolates engine vibrations from the chassis. A failing mount allows excessive movement, which the clutch must compensate for.

If you notice a thumping sound when you shift gears, the mount might be the hidden culprit. Replacing it while the engine is out is a small price for a smoother drive.

Step‑by‑Step Checklist Before You Start

- Gather a full clutch kit: disc, pressure plate, release bearing, pilot bearing (if needed), and hardware.

- Inspect the flywheel for cracks, hot spots, or excessive wear. Resurface or replace as required.

- Examine the pressure plate springs for cracks or uneven tension.

- Check the clutch disc for glazing, scoring, or worn splines.

- Replace the release bearing regardless of condition.

- If you have a hydraulic system, swap the master and slave cylinders and the hydraulic line.

- Bleed the clutch hydraulics and verify pedal firmness.

- Use a clutch alignment tool to position the disc before bolting the pressure plate.

- Torque all bolts to manufacturer specifications - typically 30 Nm for the pressure plate and 15 Nm for the flywheel bolts.

- Re‑install the engine mounts if you found any damage.

Common Pitfalls & Pro Tips

- Don’t reuse old bolts. Even if they look fine, the stretch can compromise clamping force.

- Watch the torque sequence - tightening in a criss‑cross pattern prevents warping.

- Never skip the clutch fluid flush. Old fluid can contain moisture that accelerates internal corrosion.

- If you hear a squeal after the job, the release bearing may have been installed backwards.

- Always mark the flywheel’s torque‑to‑run-out (TRO) angle on the crankshaft. It saves you a guess when reinstalling the starter.

Quick Reference: Wear Indicators Comparison

| Component | Visible Symptom | Recommended Action |

|---|---|---|

| Clutch Disc | Glazing, slipping under load | Replace with new disc (part of kit) |

| Pressure Plate | Uneven contact, cracked springs | Replace or refurbish if within spec |

| Flywheel | Scoring, hot spots, wobble | Resurface (if >2 mm thickness) or replace |

| Release Bearing | Whining or grinding when clutch pedal is pressed | Replace immediately |

| Hydraulic Line | Spongy pedal, fluid leaks | Replace line and bleed system |

| Engine Mount | Excessive vibration during launch | Replace cracked or sagging mount |

Frequently Asked Questions

Do I really need a new flywheel when I replace the clutch?

It depends on condition. If the flywheel shows scoring, cracks, or is thinner than the manufacturer’s minimum, you should either resurface it (if enough material remains) or replace it. A good flywheel ensures a smooth bite and prevents future chatter.

Can I reuse the old clutch bolts?

Generally no. Clutch bolts are designed to stretch a little during tightening. Re‑using them can lead to insufficient clamping force, which shows up as slip or a soft clutch feel.

What fluid should I use for the clutch system?

Most manufacturers recommend the same brake fluid grade (DOT 3 or DOT 4) for the clutch circuit. Use fresh, moisture‑free fluid and bleed the system after any component swap.

Is a clutch alignment tool really necessary?

Yes. It guarantees the disc sits perfectly centered on the flywheel. Misalignment can cause uneven wear on the release bearing and premature clutch chatter.

How often should I replace the release bearing?

Most mechanics replace it every time the clutch is removed. The bearing runs continuously in contact with the pressure plate, so a fresh unit eliminates one of the most common failure points.

My car has a dual‑mass flywheel. Does that change the parts list?

A DMF usually requires a specific compatible clutch kit; you can’t mix a standard single‑mass flywheel with a standard kit. If the DMF shows signs of failure, it’s usually cheaper to replace the whole assembly.