If you’re itching to replace a clutch, here’s the deal: for almost every car on the road, you have to pull the transmission out to get to the clutch. There’s no secret hatch or magic trick to skip this step. The clutch lives right between the engine and the transmission, basically squished in a spot that’s impossible to reach from anywhere else.

Trying to swap a clutch without moving the transmission? That’s like changing your shoes without taking your feet out. Sure, you might have heard stories about shortcuts or weird tricks, but for regular cars and trucks, the transmission has to come off. Even experts who do this for a living have to wrestle with big bolts, heavy parts, and tight spaces every time.

This isn’t just for making you sweat. The clutch connects directly to the flywheel, which is locked behind the bellhousing. The only way in is straight through the transmission. Some older cars and farm tractors (think pre-1980s stuff or specialty vehicles) gave you a sneaky way in, but that’s super rare now.

- What the Clutch and Transmission Actually Do

- Why Removal Is (Almost Always) Required

- Rare Exceptions and Creative Workarounds

- What’s Involved in Dropping the Transmission

- Tips, Tools, and Mistakes to Avoid

What the Clutch and Transmission Actually Do

Before you start yanking out parts, it's worth knowing what the clutch and transmission really do. The clutch is what links your engine to your wheels, but with a twist — it can disconnect them whenever you press the pedal. That lets you shift gears, come to a stop, or even sit in traffic without killing the engine.

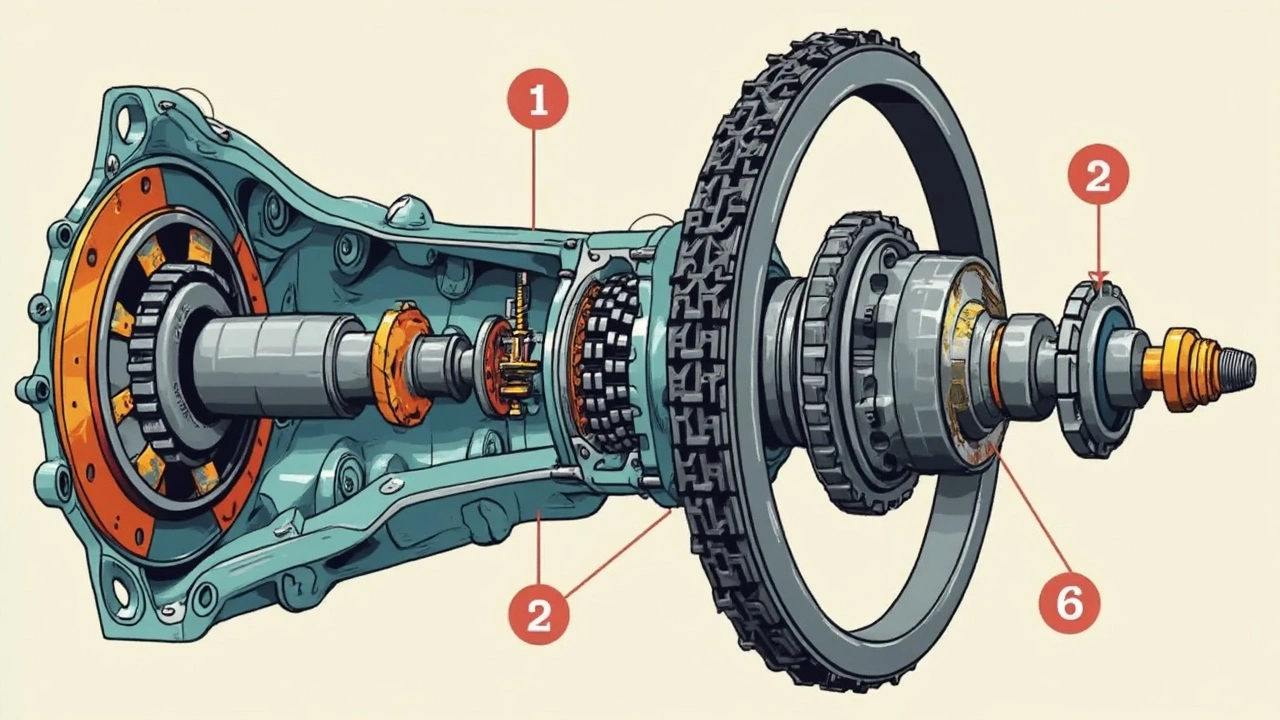

Here's how it works: Your foot pushes the pedal, which pulls the pressure plate off the clutch disc. The clutch disc is sandwiched right between the spinning engine flywheel and the pressure plate, getting squeezed hard when the clutch is 'engaged.' When you press the pedal, they separate, and the power stops flowing from the engine. Simple, but it takes a beating with every shift and stop—no wonder these things wear out.

The transmission is the box that changes how much power goes to the wheels. You select gears, and the transmission decides how fast those wheels turn based on engine speed. It’s full of gears, shafts, and (if it’s an automatic) a bunch of extra parts that do the shifting for you. Manual transmissions need the clutch to swap gears; automatics use a torque converter, which is a whole different animal.

Just to give you an idea how vital all this is, check out the stats in the table below. These parts go through a lot:

| Part | Average Number of Uses (per 100,000 miles) | Common Signs of Wear |

|---|---|---|

| Clutch Disc | Over 1 million pedal presses | Slipping, shuddering, hard shifts |

| Transmission Gears | Countless rotations/shifts | Grinding, popping out of gear |

If your clutch or transmission is trashed, the car’s not going anywhere. That’s why keeping these parts in shape—or replacing them with a clutch kit—is a must if you want a smooth ride.

Why Removal Is (Almost Always) Required

Let’s clear this up: if you want to replace the clutch, you almost always have to pull the transmission. Here’s why — the clutch sits inside a bell housing, sandwiched between the engine and the transmission. There’s no hatch, no separate panel, nothing like that. The only way you can reach it is through the path the transmission is blocking.

Automakers really didn’t leave any shortcuts when designing most clutch kits. Everything is super tight and compact under there. The flywheel, which the clutch grabs onto, is bolted directly to the engine, and the input shaft of the transmission slides through the clutch disk. Unless you can somehow bend metal or teleport parts, pulling the transmission is the move.

"You can’t properly service or inspect a clutch without removing the transmission because there’s just no access any other way," says Chris Fix, a popular DIY car repair YouTuber. "Trying to get around this step is a waste of time and might even damage something."

Most cars—no matter if you’re working on a little Honda Civic or a big ol’ pickup—follow the same setup. If you skip pulling the transmission, you’re not going anywhere. Check out this typical clutch replacement layout:

| Step | Main Task | Requires Transmission Removal? |

|---|---|---|

| Remove driveshaft/axles | Disconnecting the wheels’ power | Yes |

| Unbolt transmission | Separating from engine block | Yes |

| Access clutch assembly | Finally able to replace clutch | Yes |

You might hear about “splitting the tractor” or sliding a transaxle back a few inches on some classic farm equipment or ancient rear-wheel drive cars, but that’s niche stuff. Ninety-nine percent of the time, it’s back under the car with jacks and tools, dropping the transmission before any clutch work can happen. It’s a pain, but it’s necessary.

Trying to shortcut this step (like reaching through a starter hole or poking around the side) just doesn’t work and usually turns a headache into a total disaster. Save yourself the extra grief—pull the transmission if you want the job done right.

Rare Exceptions and Creative Workarounds

Okay, so are there actually cars where you don’t have to yank the transmission to replace the clutch? It’s rare, but there are a handful of exceptions, and some creative workarounds that ambitious DIYers try. If you’re driving something built in the last 40 years, though, don’t get your hopes up too much.

One well-known exception is some old-school, rear-wheel drive trucks—think late ‘60s or ‘70s pickups. With these, you could sometimes pull the transmission back just enough after unbolting the driveshaft and crossmember, giving you just enough wiggle room to slide the clutch out. Some tractors and even classic European cars, like Citroëns with their strange engineering (think 2CV), allow clutch swaps from the side or via access panels.

Here’s the thing: modern vehicles ditch these shortcuts entirely. Most designs pack things so tight there’s just no space, and the clutch kit is buried behind layers of parts. If you try to cut corners on newer cars, you’ll probably just damage something important or make the job way harder for yourself later.

Some creative folks will unbolt the transaxle and tilt the engine using jacks and extra muscle for front-wheel drive cars—only to shave an hour off but risk pinched harnesses, crunched exhausts, or wrecked mounts. Unless you like working on the ground with curse words and bleeding knuckles, it’s honestly not worth it. Even the pros rarely pull “just enough” out because it often causes more trouble than it saves.

- If your car is a farm tractor, some older pickup, or a Citroën, double-check the service manual—there might be an access panel in your future.

- For the rest of us: it’s standard practice—drop that transmission for a clean and safe clutch swap.

- Shortcut methods are risky and usually end up being more headache than they’re worth on cars built after the 1980s.

| Vehicle Type | Easy Clutch Access? | Comments |

|---|---|---|

| Modern Front-Wheel Drive Cars | No | Transmission removal required |

| Classic Rear-Wheel Drive Trucks | Sometimes | Check for sliding transmission trick |

| Farm Tractors | Yes | Often have clutch covers or panels |

| Citroën 2CV/DS | Yes | Special access, rare vehicle |

The bottom line: if you want a hassle-free clutch kit job, don’t rely on internet myths. The safe bet—for your hands and your car—is following the usual process and dropping the transmission fully.

What’s Involved in Dropping the Transmission

If you want to replace the clutch, dropping the transmission is where the real work kicks in. This isn’t just a quick afternoon job with a wrench. You’ll need to get the car off the ground, which usually means jack stands or a lift. The transmission is heavy—sometimes tipping the scale at 100 pounds or more on bigger vehicles—so a transmission jack is a must if you don’t feel like wrestling a chunk of metal by hand.

Before you start yanking anything loose, here’s what you’re actually dealing with:

- Disconnect the battery. Always do this first or you’ll risk shorting things out.

- Remove the driveshaft (in rear-wheel-drive cars) or CV axles (in front-wheel-drive setups) so the transmission is free from the wheels.

- Unhook sensors, wiring, and linkages—everything from speed sensors to shifter cables.

- Drain the transmission fluid. If you skip this, you’ll make a huge mess as soon as you split things apart.

- Support the engine. Sometimes the transmission is what holds it in place, so don’t let it tilt or drop.

- Unbolt the transmission from the engine block. On some cars, this means wrestling with a half-dozen or more stubborn bolts in tight spots.

- Slide the transmission back and lower it down. This part can be nerve-wracking without the right tools, especially if the car is close to the ground.

For most folks, dropping the transmission takes a few hours, even with experience. It’s pretty common to spend much longer—especially if bolts are rusted or the car’s layout isn’t friendly. On newer vehicles with lots of electronics and sensors, expect to tag and mark every wire or hose you move, so it all goes back correctly.

| Average Transmission Drop Times | Skill Level |

|---|---|

| 3-4 hrs | Experienced DIY or pro shop |

| 6-10 hrs | First-timer, home garage |

The reality is, this is one of the biggest jobs you can do with a wrench and a jack. But if the clutch is fried, it’s the only game in town unless you want to pay big shop rates. Just keep everything organized—label bolts, take photos, use zip bags for hardware—because forgetting where something goes can slow you down way more than stubborn bolts ever will.

Tips, Tools, and Mistakes to Avoid

If you’re about to tackle a clutch job, you’ll want to do it smart. Having the right tools and dodging the common traps will save you hours of frustration—and keep your knuckles scar-free. Let’s start with the bare essentials you should have for any replace clutch project:

- Jack and sturdy jack stands: Unless you’re working with a lift, car ramps or tall jack stands are a must so you’re not crawling under 10 inches of steel.

- Socket set (metric and SAE): Some transmissions mix sizes, so don’t get stuck halfway.

- Breaker bar and extensions: These bolts are factory-tight. You need leverage, or they won’t budge.

- Transmission jack or a buddy: Transmissions are heavy and awkward. Don’t trust your regular floor jack to hold it safely.

- Pry bar: Separating the transmission from the engine can take some muscle.

- Alignment tool: Every clutch kit worth its salt includes a plastic tool for lining everything up. Don’t skip it.

Here are a few tips from the trenches:

- Double-check you’ve disconnected the battery. Starter wires are right in your work zone.

- Grab a notepad or your phone and snap photos as you tear things apart. When putting it back, guesswork is lazy and can cost you.

- Bag up bolts and label them. Many of these screws are different lengths even if they look the same at first glance.

- Don’t cheap out on jack stands. Safety isn’t a line to cross.

- Invest in a torque wrench. Guessing torque is the fastest way to shear a bolt or end up with a rattle.

Mistakes? Here’s what trips up even experienced folks:

- Not supporting the transmission fully before unbolting it from the engine. These things drop fast.

- Forgetting to replace the pilot bearing or throwout bearing—most clutch kit changes include these, but some skip them.

- Using old bolts that stretch or corrode. If the transmission removal was a pain, putting it back together with bad hardware is worse.

- Rushing the alignment. A crooked clutch disc means your brand new clutch could fail in weeks or just never work right.

On average, a home mechanic can expect the full job to take 6-12 hours, depending on experience and car model. Here's a quick comparison of common clutch job times for popular cars, based on real-world repair data:

| Car Model | Average Time (Hours) |

|---|---|

| Honda Civic | 6-8 |

| Ford Mustang | 8-10 |

| Toyota Tacoma | 10-12 |

Every bolt, every step, every tool matters when you’re working to replace clutch components. Prepping right can be the difference between a weekend win and a driveway disaster.