Ever been caught with a failing clutch pedal, or just plain curious about what your manual transmission is truly capable of? There are stories of truckers tackling mountain passes without a clutch, of rally drivers making split-second clutchless shifts, and of commuter cars limping home thanks to a bit of mechanical know-how. But is clutchless shifting good for your vehicle, or just a mechanical party trick with a hefty repair bill hidden in the punchline?

How Manual Transmissions Actually Work: The Science Behind the Shift

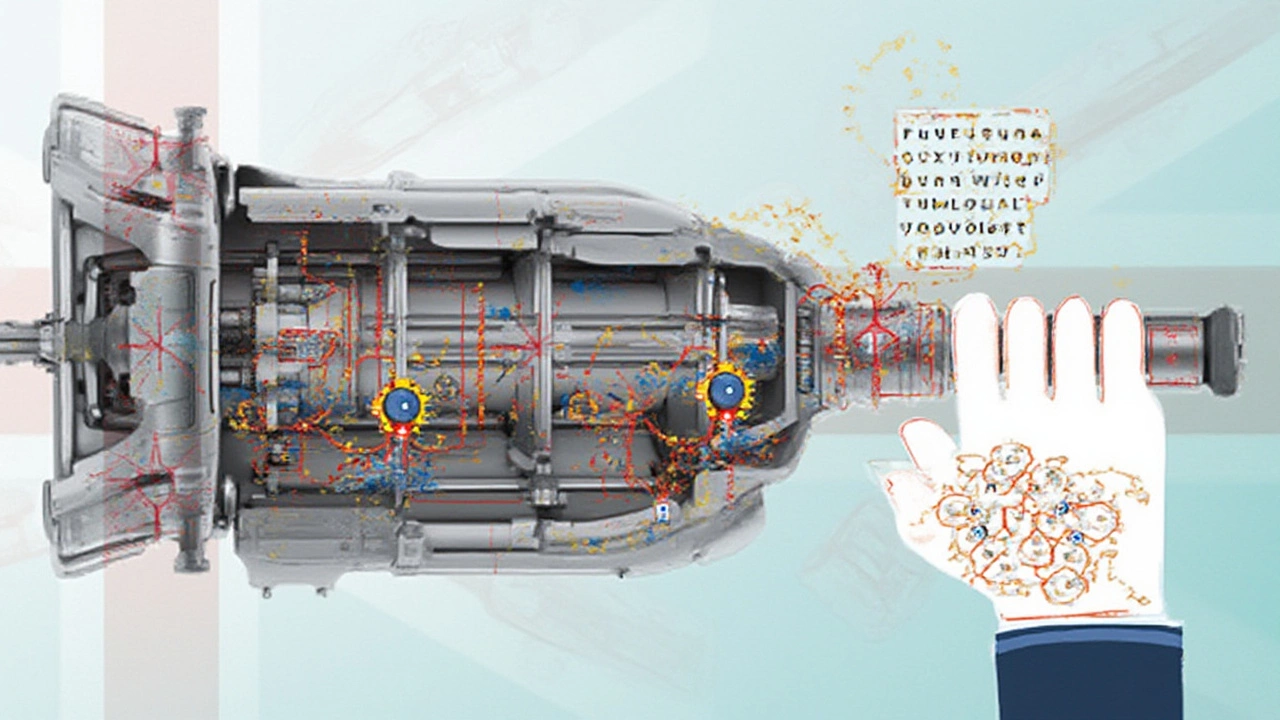

To understand if you can shift gears without using the clutch, let's break down what happens inside your gearbox. In a typical manual, you've got your engine's power coming in one side and wheels spinning out the other. In the middle are teeth, collars, and synchronizers—tiny parts that line up perfectly when you shift. Normally, your clutch acts like a referee, briefly separating the engine from the transmission, so gears can slide together cleanly without crunching. You press the pedal, the clutch disengages, the spinning stops, you change gears, then the clutch re-engages and you’re off.

Now, picture skipping the referee: the engine and transmission keep spinning together. If you aren’t careful, that’s when you get the classic grinding noise—metal teeth trying to force a handshake during an earthquake. The thing is, it’s possible to do it smoothly, but you need to synchronize the rotational speeds yourself by using the throttle and timing. Professional drivers and truckers call this "rev matching" or "floating gears." Some folks even do it for fun on vintage motorcycles and trucks. It’s definitely a learned skill, not an everyday necessity—unless your clutch truly bites the dust in the middle of nowhere.

Data from a 2023 survey of auto mechanics (reported by Auto Technician Review) showed that almost 70% had dealt with cars sporting clutch damage from failed or repeated attempts at clutchless shifting. On the flip side, when done right, clutchless shifting can let you nurse a failing clutch back to base or present a challenge for drivers who love feeling connected with the machine. That said, manufacturers never recommend this for routine driving. You might see instructions for "double clutching" in older owner’s manuals, but that’s a different move—and usually intended for vintage transmissions without modern synchronizers.

Beneath all those moving pieces, transmission oil is always working to keep heat and friction under control. If you mess up a shift, you can actually add wear to your synchronizer rings or even bust some gear teeth, especially over time. A clutchless shift is not as forgiving as a shift with the pedal pressed. And if your ride uses special performance parts or is carrying a heavy load (like in semi-trucks), mistakes get more expensive fast. Classic cars, some Japanese imports, and older European sedans are notorious for having gearboxes that "tolerate" clutchless shifts, but even then, most owners wouldn’t risk frequent rides without the pedal.

Yes, You Can Shift Without the Clutch (But Should You?)

The short answer is: yes, you can shift gears in a manual car without using the clutch. But it’s not something you should make a daily habit of if you want your gearbox to live a long, happy life. Here’s how it actually works. You have to match the speed of your engine to the speed of the wheels perfectly—otherwise, gears clash and teeth grind. Think of it like trying to time a hop onto a moving merry-go-round; get it just right, and you'll land perfectly. Miss the timing, and it's a bumpy ride.

Let’s look at a simplified step-by-step for upshifting without the clutch in a passenger car:

- Accelerate in your current gear up to a mid-range RPM (let's say 3000 for a typical sedan).

- Let off the gas and gently tug the shift lever out of gear just as you feel the power drop (the lever should slip out if you're at the right RPM).

- Move the lever into the next higher gear; wait until the engine revs drop to where the new gear wants to engage (you’ll get there by feel, but as a reference, second gear likes around 2000 RPM in many cars).

- Slide the shifter into the target gear with gentle pressure. If it resists, you’ve missed the match—try again with more patience.

- Gently roll back onto the gas.

Downshifting is harder, since you need to increase the engine speed (rev matching by blipping the throttle) as you slot into a lower gear. Racing drivers master the "heel-and-toe" technique for precisely this reason—but it’s not beginner stuff. Miss the timing, and that lurch you feel makes your mechanics wince in spirit. On motorcycles—where clutches are tiny and gearboxes are tougher—you’ll even find people making clutchless upshifts as standard practice and the design often tolerates it better.

The mechanics of why it works are simple enough: gears want to join when their speeds match. Synchromesh (the synchronizer rings in modern gearboxes) makes up for speed differences by using friction to even things out, but it’s not magic—if you don’t use the clutch, the synchronizers do all the heavy lifting, and they’re far from indestructible. Over long periods, this will eventually wear them down.

It’s a trick worth knowing. There’s even a certain thrill when you get a shift right—purely by timing and touch. But don’t mistake it for a secret hack that saves time or effort. Auto engineers design modern gearboxes assuming drivers will use a clutch, and consistent clutchless shifting usually means an earlier date with gearbox repairs. If you do end up with a dead clutch, clutchless shifting can get you out of a jam. Your car won’t roll without the clutch engaged at a stop, so starting from rest is a challenge—most pull away by turning the ignition while in first gear. Awkward and a bit jarring, but it works in a pinch.

Here's a quick look at the risks of clutchless shifting versus regular use:

| Shifting Method | Pros | Cons | Wear & Tear |

|---|---|---|---|

| With Clutch | Smooth, reduces stress on gears, recommended | Clutch wears out over time | Clutch: High Gears: Low |

| Without Clutch | Possible if skilled, useful if clutch fails | Harder to master, risk of gear grind | Clutch: None Gears & syncros: High |

And yes, there are some fun facts here: In certain high-speed racing situations, even Formula One cars shift without a clutch, thanks to computer-controlled gearboxes that rev-match more accurately than any human. But those gearboxes are built—and rebuilt—far more often than your daily driver’s transmission ever will be.

Tips, Warnings, and Must-Knows If You Want to Try Clutchless Shifting

Feeling confident enough to give clutchless shifting a shot? Let’s talk about survival tips—and a few caution signs. Done wrong, it’s a gear grinder, but done right, it’s the mark of someone who really understands their car. Here are essentials to keep in mind:

- Don’t practice on a crowded road—Empty parking lots or quiet backroads are your friends when learning. You need space to mess up and recover.

- Find your gearbox’s “sweet spot”—Most cars have a sweet RPM where the shifter almost floats out of gear with no resistance. Get to know this feel so you’re not yanking or forcing anything.

- Be patient with your shifter—If it doesn’t want to go, don’t muscle it. Forcing a shift means broken teeth or worn synchronizers.

- Understand that downshifting is twice as hard—You have to catch the revs perfectly, or your car will shudder hard and you’ll hear the “crunch.”

- This is not a shortcut to “coolness”—Mechanics will spot the wear. If you’re not dealing with a clutch emergency, your car (and wallet) are happier with regular shifting.

- Clutchless shifting on motorcycles? Usually safer, but only on upshifts. Many modern bikes are designed for clutchless upshifts but still recommend the clutch for downshifting.

- If you’re learning for emergency preparedness—Make sure you also know how to start a manual car in gear if your clutch is completely dead. This can get you home, but it won’t be pretty.

- Be alert to new noises—Hear a sudden grinding, whining, or difficulty getting into gear after practicing? You might have already damaged syncros or gear teeth.

Still considering making clutchless shifting a regular thing? Look at these average repair costs: synchronizer rebuilds on common manual transmissions hover around $1200 to $2500 as of summer 2025, based on repair shop surveys from the Midwest. Gear tooth replacement can cost much more, especially on newer cars or anything with limited parts supply.

One little-known fact: Some heavy-duty trucks and buses are designed for clutchless shifting once in motion—the clutch is really only used for starting and stopping. This drives home the point: vehicle design dictates what’s safe and what’s risky. If you’re rocking a 1995 Civic, you’ll probably get away with the occasional clutchless shift, but by 2024 most cars expect you to use that pedal every time.

If you want your ride to last, remember the golden rule: just because you can doesn’t mean you should. Want to impress friends or prove your mechanical “feel?” Save it for the right moment—like if someone bets you can’t get home with a dead clutch, or if you’re showing off a cherished beater that’s already on borrowed time. For daily driving, give your gearbox the gentle treatment it deserves and let the clutch do its job.

For those who want to geek out further, here’s a stat: the average modern manual clutch, when driven gently and shifted correctly, should last between 80,000 and 120,000 miles according to a 2022 industry analysis by Motor Research Group. Throw a few hundred clutchless shifts at those same cars, and mechanics in the same study reported synchronizer issues cropping up 30% earlier. The data’s clear: clutchless shifting is a survival skill, not a daily driving style.