Suspension-Engine Symptom Checker

Check Your Symptoms

Select symptoms you're experiencing to determine if your engine issues might be caused by suspension problems.

Results

Select symptoms to see analysis.

When a vehicle's Suspension system holds the wheels, absorbs shocks, and keeps the chassis level starts to go bad, you’ll often feel it in the engine bay. A rattling ride isn’t just uncomfortable - it can be a warning that the engine is taking a beating. In this guide we’ll walk through exactly how a failing suspension can hurt your engine, what symptoms to watch for, and how to keep both systems happy.

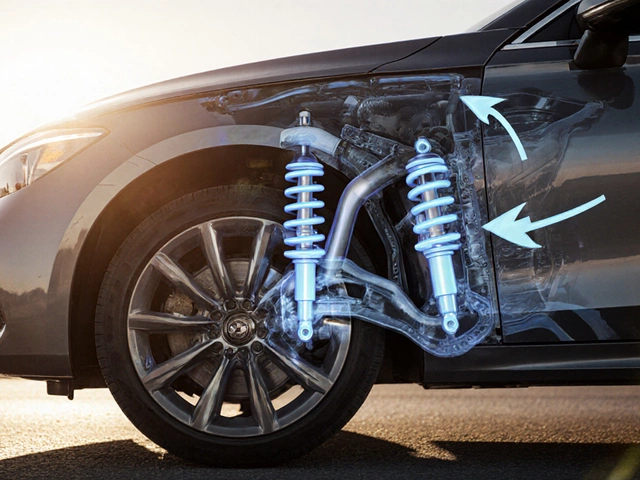

How the suspension and engine work together

The engine generates power, but that power has to travel through the drivetrain to the wheels. The suspension sits between the wheels and the chassis, acting like a buffer. When the suspension does its job, it isolates the engine and transmission from road‑induced forces. If the buffer weakens, those forces travel straight into the engine mounts, crankshaft, and even the oil pan.

Key components that link the two systems include:

- Shock absorbers convert kinetic energy from bumps into heat

- Struts combine a shock absorber with a structural support

- Control arms connect the wheel hub to the chassis

- Engine mounts rubber or hydraulic cushions that isolate engine vibration

When any of those suspension parts wear out, the engine feels more vibration, torque twist, and lateral stress.

Common suspension faults that stress the engine

Here are the usual suspects that can translate into engine trouble:

- Worn shock absorbers or struts - they let the wheel bounce excessively, causing the chassis to pitch and yank on the engine mounts.

- Loose or broken control arms - misalign the wheels, leading to uneven torque distribution.

- Failed bushings plastic or rubber cushions at suspension pivots - create metal‑on‑metal contact that transfers vibration.

- Worn ball joints - allow wheel wobble that can twist the drivetrain.

- Broken sway bar links - reduce chassis stability, making the engine rock side‑to‑side.

Each of these issues adds extra load to the engine mounts. Over time the mounts can crack, allowing the engine to shift more dramatically. That shift can cause oil starvation, mis‑fires, and even premature bearing wear.

Warning signs you’re damaging the engine

Different problems look similar, but a few clues point straight to suspension‑related engine stress:

- Excessive vibration at idle - especially when you press the accelerator lightly.

- Engine rattles that get louder over bumps.

- Unusual noise from the engine bay when turning sharply.

- Visible oil leaks around the engine mounts.

- Reduced fuel efficiency - the engine works harder to compensate for uneven power delivery.

If you notice any of these, it’s a good idea to double‑check your suspension before the engine starts showing wear.

Comparison of symptoms: Suspension vs. Engine problems

| Symptom | Likely Suspension Cause | Likely Engine Cause |

|---|---|---|

| Vibration at idle | Worn engine mounts or broken control arm | Mis‑firing plug, worn crankshaft damper |

| Noise over bumps | Bad shock absorbers/struts | Loose exhaust heat shield |

| Pulling to one side | Wheel alignment, broken sway bar link | Uneven tire wear, brake drag |

| Reduced power on hill climbs | Control arm wear causing traction loss | Clogged fuel filter, weak spark |

| Oil leak near engine block | Engine mount seal failure from excessive motion | Worn gasket, cracked pan |

This table helps you pinpoint whether the root cause is likely in the suspension or deeper in the engine.

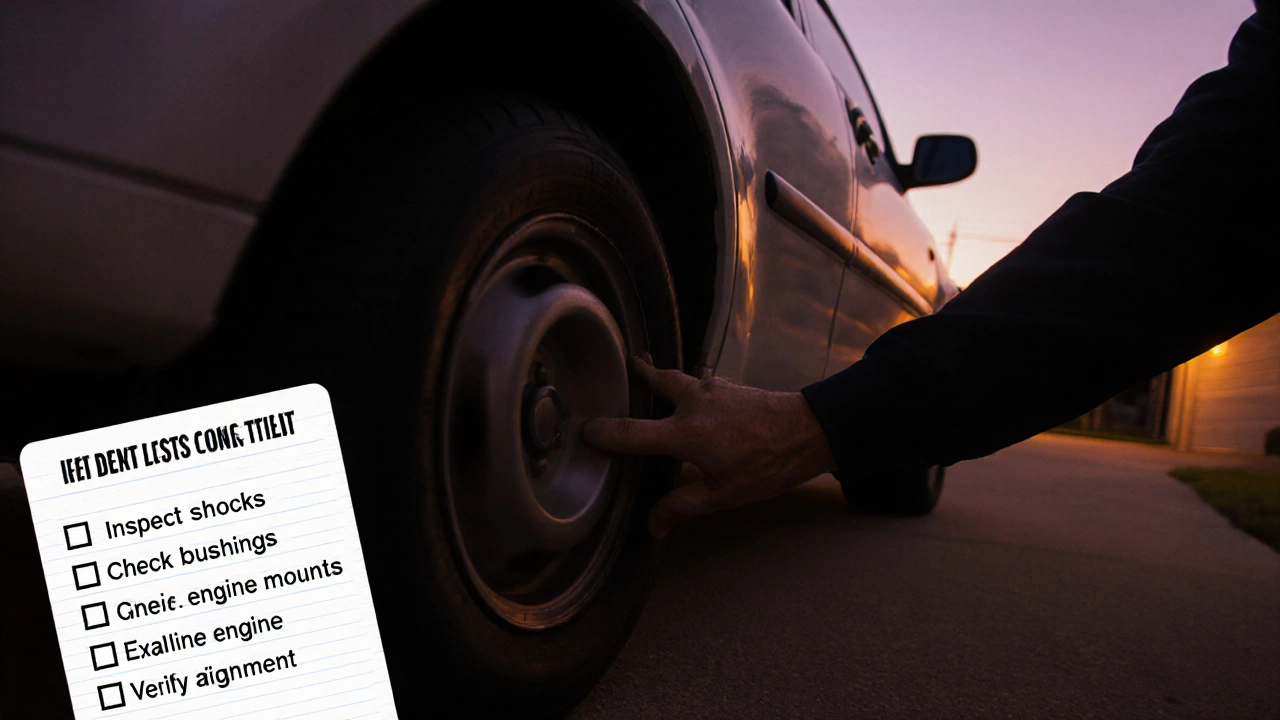

Preventive checks and simple fixes

Before a minor suspension fault turns into an engine‑damage nightmare, run these quick checks:

- Push down on each corner of the car. If it bounces more than once, the shock absorber or strut is suspect.

- Inspect all rubber bushings for cracks or leakage. Replace any that look dry or fragmented.

- Look at the engine mounts. Any visible cracks, oil seepage, or looseness means they need swapping.

- Check wheel alignment with a DIY alignment kit or at a shop - mis‑alignment puts side forces on the drivetrain.

- Listen for clunking when you go over a pothole; that often points to ball joint or control arm wear.

If you catch these early, a simple part swap - usually under £150 for most shocks or mounts - can save you from a costly engine rebuild later.

When to seek professional help

Some suspension jobs are best left to a garage, especially when dealing with mounting points that affect the engine:

- Full replacement of struts that require spring preload tools.

- Alignment after any suspension component change.

- Diagnostic scan that shows engine codes related to vibration (e.g., P0300 random misfire) combined with suspension wear.

- Any situation where you suspect a cracked engine block from mount failure - that’s a serious repair.

Professional mechanics have the lifts and torque specs needed to tighten everything to factory standards, ensuring the engine stays protected.

Bottom line

A bad suspension engine damage scenario is more common than many drivers think. Worn shocks, broken control arms, or collapsed mounts can turn a smooth ride into a shaking nightmare that accelerates engine wear. By staying alert to the signs, doing a few quick visual checks, and fixing suspension parts before they fail, you protect both your comfort and your engine’s lifespan.

Frequently Asked Questions

Can bad shocks really damage my engine?

Yes. When shocks or struts lose their ability to dampen road impacts, the chassis moves more violently. That motion pushes against the engine mounts, causing them to wear out faster and allowing the engine to shift, which can lead to oil starvation, bearing wear, and ultimately expensive engine repairs.

What’s the difference between a shock absorber and a strut?

A shock absorber only damps movement, while a strut combines a shock absorber with a structural support for the suspension. Struts also take up some of the load that would otherwise go to the chassis, so a failed strut can affect both handling and engine stability.

How often should I replace my engine mounts?

Most manufacturers recommend checking mounts every 60,000‑80,000 miles. If you notice excessive vibration, oil leaks near the mounts, or visible cracks, replace them sooner - even if mileage is lower.

Will a wheel alignment fix engine vibration?

A proper alignment removes side‑load forces on the drivetrain, which can reduce vibration caused by uneven torque. However, if the vibration stems from worn shocks or engine mounts, alignment alone won’t solve it - you’ll need to address those parts too.

Is it safe to drive with a broken control arm?

No. A broken control arm can let the wheel move unpredictably, putting extra strain on the drivetrain and engine mounts. It also compromises handling, increasing the risk of loss of control, especially at higher speeds.